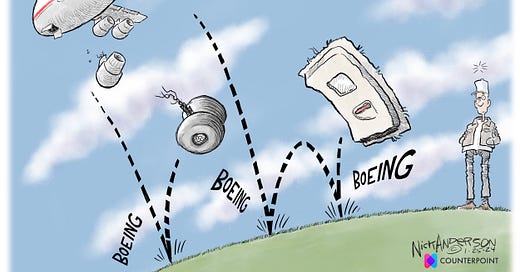

I'm reading more and more about a change in Boeing's corporate culture decades ago that led to a slow degradation of Boeing's quality control. It's the same old story; prioritizing short-term profits over safety and quality. It was just a matter of time before it started to catch up with them.

Keep reading with a 7-day free trial

Subscribe to Pen Strokes to keep reading this post and get 7 days of free access to the full post archives.